Operating Procedures

To thoroughly clean all parts and remove burrs and sharp edges to ensure unblemished parts

- Free From burrs and sharp edges

- To remove rust and debris from the parts

Stable component accuracy

- The supply chain with its own component inspection system

- To ensure machining accuracy for assembly operation

- The on-time quality control

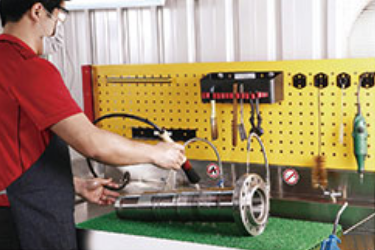

Stable spindle accuracy

- The bright, clean and constant temperature assembly room

- The precision assembly within tolerance specification

- The professionally trained & dedicated engineers

- The life running tests

- The temperature and noise test

- The vibration test

- The temperature, vibration, run out, clamping/ unclamping force, rigidity,hydraulic-pneumatic circuit, electrical connectors and external appearance inspection

- The complete inspection specification to ensure the spindle quality

Application

Spintrue develops and markets spindle for precision machining in the optical industry, medical technology, semi-conductor machining, aircraft industry and tool and die making as well as the automotive industry.

Optical Industry

Medical Technology

Semi-conductor Machining

Aircraft Industry

Tool and Die Making

Automotive Industry

Services & Abilities

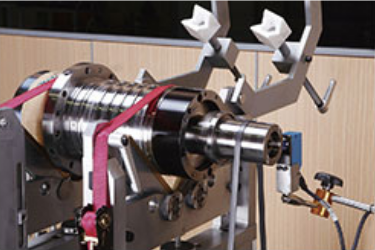

Research & Develop

Spindle Customization:

- Professional senior design team, providing complete spindle solutions

- Customized spindles can meet various needs of customers

Manufacturing Capability

A bright and spacious assembly environment, introducing a production management system to reduce waste and enhance assembly efficiency, and flexible production can be changed according to customer needs.